Suzuki Hayabusa Turbo Gsx 1300R 2016

TURBO TRANSFORMATION MADE BY WORKSHOP ROBY MOTO HAYABUSA POWER OF 321.9HP@1.6bar

WE SHOW BELOW THE PREPARATION WITH INFORMATION OF YOUR SAFE INTEREST and ALL THE PARTS TO BUY FOR THE TRANSFORMATION FOR THE HAYABUSA TURBO

Suzuki Hayabusa Turbo GSX 1300R first generation up to 2007 second generation 2008-2015, while this preparation was done on a third generation HAYABUSA motorcycle produced from 2016 until 2021, the fourth and last generation is currently in production starting from 2022.

RPM limiter set at 12000 RPM with inverted H steel connecting rods and molded pistons supplied by ProtoXide. The engine runs off so violently that even the rev limiter struggles to keep up with it .. in fact we read 12214 RPM from the photo!

As you know this original production bike reaches 299 KM / H as a maximum speed.

The speed achieved by our Turbo transformation manages to reach 258 KM / H on the bench, but only in 4 Gears and the bike has 6 gears!

Originally this engine comes with two coils with lost spark. We have converted the CDI 4-coil ignition system. Clearly the original tachometer no longer marked the engine rpm correctly and thanks to a dedicated controller we converted the rpm correctly, so as to always use the dashboard with the original tachometer.

With our preparation we were able to achieve the horses of the standard bike a little more than half of the laps of use, exactly at 8000 laps! This makes you understand that we have decided in advance to have a good reactivity starting from low revs, even if the driveability is really compromised!

Material used in this preparation with Turbo transformation with increased displacement:

Reinforced forged pistons from turbo transformation. COMPRESSION RATIO FROM 9: 1

Inverted H-shaped steel connecting rods

Stroke crankshaft with increased displacement

3 different lengths you need to know which block you use. Available in 3-5 weeks

Specific Hayabusa 3rd series head studs

Camshafts for turbo conversion with specific timing

32 pieces reinforced valve springs and NIMONIC valves

4-1 stainless steel exhaust manifold with internal or external wastegate

AFR carburetion instrumentation for carburetion with wide band probe

Reinforced multilayer metal head gasket

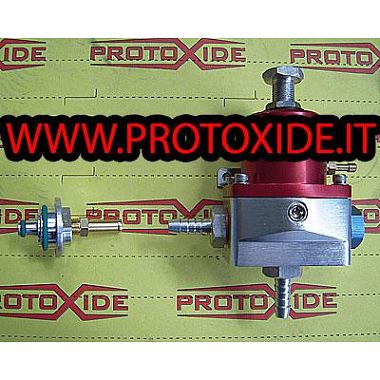

Fuel pressure regulator for double diaphragm injection turbo

Air-water intercooler integrated in the intake manifold

Additional water radiator for air-water intercooler.

Ignition capacitive amplifier control unit with 4 CDI coils

COMPLETE engine management unit

All the original sensors are used, no modification is necessary to the sensors or to the original phonic wheel.

The original control unit is removed and only our control unit already programmed with our wiring is used.

The control unit uses the original phonic wheel together with the ORIGINAL phase sensor!

Long wiring for our control unit to be shortened with specific colors indicated in the software and dedicated thicknesses and shields.

Increased fuel pump

Base or shim to decompress engine and compression ratio

Modified injection flute

Oversized injectors Turbocharger on bearings with reinforced wastegate

Turbocharger on bearings with external TialSportWastegate connection

Turbo thrust sleeve made of ProtoXide to take up as little space as possible and avoid splitting the sleeves, given the supercharging pressure we use and so as to avoid slips and breakage of the sleeves.

Exhaust back pressure sensor connected to the control unit for carburation strategy

Controller to re-calibrate the tachometer

Exhaust gas meter (probe + nipple + 4-digit digital instrument with programmable relay)

Exhaust downpipe and complete exhaust up to the silencer Handcrafted by Roby Moto

ProtoXide Boost your Life! T-shirt

Contact us: